| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : D6D Track Roller

Model Number : Hengte120

Certification : ISO、CE

Place of Origin : China

MOQ : 5 pieces

Price : $4.90 - $20.00/pieces or Price

Payment Terms : T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow

Supply Ability : 10000 PCS/Month

Delivery Time : FOB Xiamen or any Chinese port:25-30days . If there are any parts in stock ,our delivery time is only 7-10 days.

Packaging Details : Export Packaging

Weight : 25kg

Usage : Construction Machinery

Surface Treatment : Heat Treatment

Impact Resistance : High

Installation : Easy

Technology : CNC machining center

Size : Standard

Heat Treatment : Yes

| Detail Information | |||

| Material: | 40Mn2 Steel | Technique: | Forging |

| Quality: | Heat Treatment HRC 53-57 | Dimension: | Standard |

| P/N: | CR6088/CR6089 | OEM/ODM: | Available |

| Highlight: | D6R Bulldozer Bottom Track Rollers, Bottom Track Rollers CR6088, Double Flanged Track Rollers CR6089 | ||

Product Description

Hengte 120 Track Roller Yellow Color Bulldozer Spare Parts

The track roller is a vital part in tracked engineering machinery, guaranteeing stable machinery operation and boosting its overall efficiency.

The manufacturing of the supporting wheel initiates with the welding of its body. Afterward, it undergoes a meticulous machining procedure utilizing a specialized vertical CNC lathe designated solely for this component. This precise approach guarantees accurate concentric alignment of the wheel body, resulting in notable quality advancements compared to wheel bodies that only undergo minimal machining after welding.

Manufacturers who focus on support wheels differentiate themselves through offering personalized services that attentively address their clients' unique needs. These bespoke solutions may involve adjustments to factors like load-carrying capacities, operational configurations, size specifications, and other vital aspects, guaranteeing a smooth integration and perfect fit of the support wheels within the customers' mechanical systems.

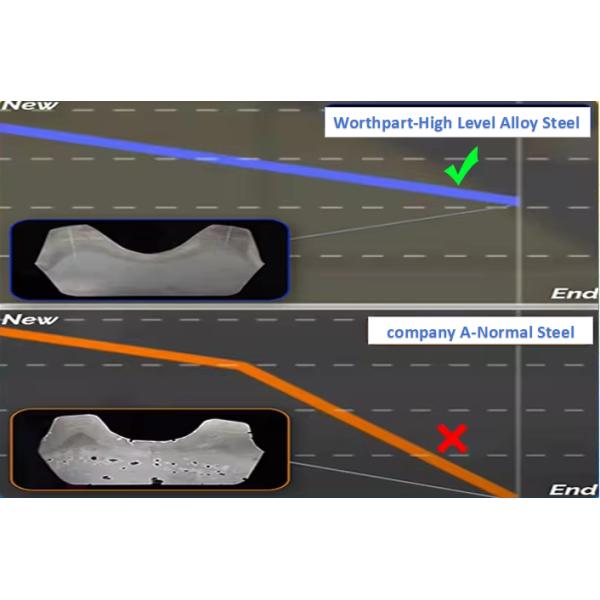

In the extensive process of designing and manufacturing model support wheels, a thorough performance assessment is undertaken. This comprehensive evaluation covers critical aspects such as load-bearing capacity, wear resistance, impact durability, sealing efficiency, and other vital considerations, ensuring that the wheels perform optimally in practical applications.

Within the six-month warranty period, customers have the ability to promptly submit clear images featuring the company logo whenever they encounter issues such as oil leakage or wheel damage. In these instances, new wheels will be dispatched swiftly and without any complications, ensuring no unnecessary delays.

|

|

2000 Working Hours HRC53-57 50mn Undercarriage Parts Bulldozer Track Roller For Hengte 120 Images |